Features:

Polypropylene fiber anticorrosive tape is a new type of environmental protection anticorrosive product without pollution and harm. It can be widely used in oil, natural gas, chemical industry, urban construction of water supply and drainage, oil and gas, gas transportation steel pipeline and steel buried storage tank of external anticorrosion and repair engineering. It is the recommended product designated by the Ministry of Construction and the State Environmental Protection Administration to replace "asphalt glass fiber cloth" and "coal epoxy asphalt". It has the characteristics of simple construction, impact resistance, aging resistance, tensile resistance, ultraviolet radiation resistance and high bonding strength.

The product base material is unique modified polypropylene braided fiber cloth, using butyl rubber modified asphalt as anti-corrosion adhesive layer. Its base material is fiber structure can effectively resist creep damage caused by soil stress, and its corrosion resistance life is proved to be more than 50 years by aging test. The test indexes are much higher than SY/ T0414-2007 standard requirements, and fully meet the American ANSI/AWWAC209-00 and NACEMR0274-95 indexes. It is the best choice for pipeline cold anticorrosive construction tape, and also the most economical choice for anticorrosion.

Performance indicators

| Serial number | Project name | Polypropylene reinforced fiber anticorrosive tape |

| 1 | Number | SXB |

| 2 | Color | Black, gray, green or other colors |

| 3 | Specifications | 50、75、100、150、250、300 |

| 4 | Ply(mm) | Basilemma 0.30 0.30 0.55 0.40 0.50 A rubber 0.85 0.90 1.10 0.95 1.00 1.05 The total thickness1.15 1.20 1.40 1.50 1.60 1.65 |

| 5 | Tensile strengthMpa | ≥60 |

| 6 | Peel strengthN/cm | On primed steel ≥45 On the tape backing material ≥25 |

| 7 | Dielectric strengthkv/mm | ≥30 |

| 8 | Volume resistivityΩ.m | >1x1012 |

| 9 | Water vapor transmittance(24h) mg/cm2 | <0.45 |

| 10 | Heat aging test(2400h) | <25% |

| 11 | Uv aging resistance(168h) | ≥80% |

| 12 | Bibulous rate | <0.35% |

| 13 | The use of temperature(℃) | 5-50 |

Usage:

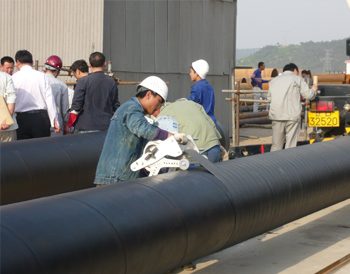

(1) Surface treatment of steel pipe: remove rust, welding slag, burr, oil, dirt and keep it clean and dry. Manual rust removal should reach St3 level, mechanical rust removal should reach Sa2 level, and meet the requirements of SYJ4007-86.

(2) primer: special primer should be used, away from the fire source when used, stir evenly and evenly coated with clean brush, roller or other mechanical methods. Primer dosage: manual coating 12㎡/L mechanical coating 20㎡/L

(3), to dry primer table (generally 5 to 10 minutes later) can be wrapped.

(4), trench back filling: after the quality inspection acceptance can be ditched.

Transportation and storage:

(1) In the process of transportation, the adhesive tape can prevent exposure, rain and deformation.

(2) In transportation or storage by 5℃ below the sudden freezing, need to be stored at about 20℃ for 48 hours before construction.

(3) It should be stored in a cool warehouse with the temperature of 5 ~ 30℃ and the temperature < 75℃. The storage period is 12 months, and it is far away from heat source and open fire.