I. Product Overview

Photosensitive curing FRP prepreg belt is the first domestic brand product independently developed after summarizing the advantages and disadvantages of similar foreign products. The product is being developed as a protective material for directional pipeline crossing. Therefore, the product structure design of improving strength, hardness, rigidity, toughness and reducing stress concentration caused by hollow drum is the highlight of this technology development. After a year of development and applications of more than two years, light curing FRP presoak belt after dozens of pipeline crossing for application, and through the two xinjiang hotan collect jade river overall test of coating protection, has become the technical indicators far ahead of other similar products at home and abroad, application is very mature technology products. The technologies we exclusively use in this product include: cloth mat composite braided fiber technology, epoxy-polyurethane photosensitive resin, surface dispersion strengthening technology, squeeze dipping technology, embedded lap hollow drum coating technology, flexible epoxy coating bottom bonding technology. Through the use of these technologies, the photosensitive curing FRP protective sleeve prepreg belt has the following technical performance characteristics.

Two, product features

2.1 High strength, high rigidity, high deformation resistance. As a protective material for pipeline crossing, it is necessary to have high strength and deformation resistance in order to prevent being torn by gravel in the hole. Due to the use of advanced cloth felt composite braided reinforced fiber technology and extrusion impregnation technology, After curing, the tensile strength reaches 280MPa and the deformation resistance load reaches 350N/5mm, which is 2-5 times that of other similar products at home and abroad (the tensile strength of other products is less than or equal to 80MPa and the deformation resistance load is 40-140N/mm).

High toughness and crack resistance. By using epoxy-polyurethane photosensitive resin, the prepreg band of photosensitive curing GLASS fiber reinforced plastic protective sleeve can reach 5° without cracking in three-point bending test. This index is 2 times higher than other similar products at home and abroad (other products do not crack at 2°) and the corresponding technical requirements of 3-layer PE and fused epoxy powder coating (see related technical standards). Thus, the protective sleeve will not be crushed in the extreme case when it is subjected to large local deformation.

2.3 High adhesion to 3 layers of PE and fused epoxy powder coating. All photosensitive fiberglass protective sheath products are not sticky themselves and must be bonded to the underside by a low coating material in the middle. In this respect, many people only consider the bonding strength, but do not consider whether the bonding material itself can withstand the force under the condition of extreme crossing, so many bonding failure is not from the insufficient bonding force, but from the fragmentation of the bonding material itself! Therefore, our company develops solvent-free flexible epoxy coatings. The coating is mutually soluble with the prepreg belt of photosensitive curing GLASS fiber reinforced plastic protective sleeve, and used in a complete set. The bonding of steel reaches 13MPa (reaching the level of double layer epoxy patch coating), the bonding of fused epoxy powder coating reaches 12.7mpa, and the 3-layer PE coating reaches 4-10mpa (higher than that of epoxy glass fiber reinforced plastic protective coating). The most valuable is that the coating has excellent flexibility, bending 5° does not crack, thus ensuring that the adhesive will not fail under the condition of extreme crossing.

2.4 High surface hardness. And iron and steel materials, in order to obtain high anti-scratch, anti-wear, anti-puncture performance, in improving the overall strength of the material at the same time, must undertake surface hardening treatment, such as we commonly used gear, tool, shaft and shaft sleeve is through surface hardening treatment. In the production of photosensitive curing GLASS fiber reinforced plastic protective sleeve prepreg belt is also used in the steel industry surface hardening technology, the use of diffusion strengthening technology, so that through the overall coating with photosensitive curing glass fiber protective sleeve Bacor hardness reached 70, and other similar products only 40-50. Imagine if one day, the hardness of the photocured fiberglass sheath was greater than that of the rock passing through the hole. We're in for a lossless ride!

2.5 Hollow drum lap integral coating technology. Cavitation drum, especially continuous cavitation drum is one of the main reasons for the damage of pipe passing through the outer protective coating. To this end, our company adopts double-layer staggered production technology, so that the photosensitive curing FRP protective sleeve prepreg belt has two cloth, two felt and five oil staggered structure, with such a product coated pipeline can completely eliminate the continuous annular lap area of the empty drum, and realize the head lap four side bonding, forming the most strong protective layer. The safest pass-through protection is currently available only with preimpregnated bands of photocured FRP protective jackets.

2.6 High shrinkage rate. The prepreg belt of photosensitive curing FIBERglass protective sleeve has a high shrinkage rate of 1.5-3%. 10 times of other products at home and abroad (1.5‰ of other products). What are the benefits of a high shrinkage rate? The meaning of shrinkage is the same as that of thermal shrinkage sleeve, which is necessary for pipeline filling.

Iii. Form of product provision

According to different use requirements, such as ordinary buried pipeline filling, through pipeline filling, through pipeline overall coating, design the corresponding different types and structures of products. Cnd-500 is a FRP structure with one cloth, one felt and three oils, which is suitable for filling the common buried pipelines. Cnd-870 model is two cloth, two felt and five oil structure, suitable for clay soil through the production of filling; Cnd-870h is a structural product of surface hardening technology of two cloth, two felt and five oil belts, which is suitable for making pebbly soil through pipeline. ; Cnd-870hw is a product of two cloth, two felt and five oil, with surface hardening technology and staggered edge structure, suitable for integral coating of gravel soil crossing pipeline. Each product is customized according to the diameter of the pipeline, with light blocking bag packaging, carton packaging. Supporting materials include: special gloves, special rubber hammer, winding film, transparent tape.

Four, product performance

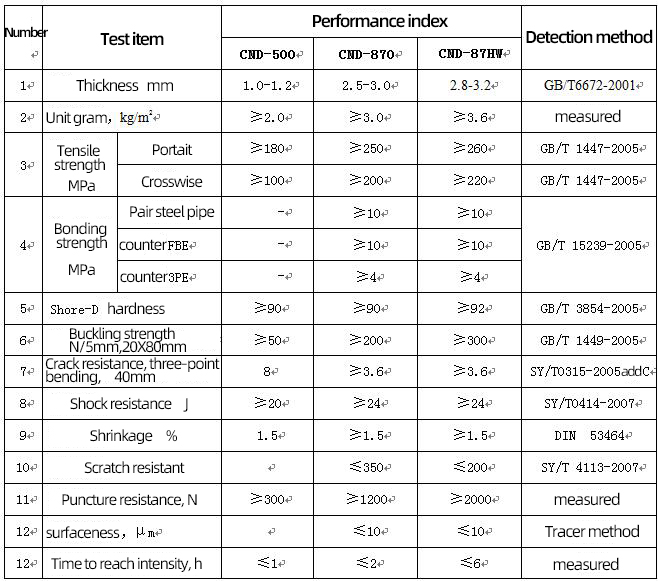

Main technical performance indexes of photosensitive curing GLASS fiber reinforced plastic protective sleeve prepreg belt

Five, product use

The filling mouth of the common pipe section of the new pipeline, the filling mouth of the horizontal pipe section of the new pipeline, and the overall covering of the horizontal pipe section of the new pipeline.

Six, use reference

6.1 The construction of the light curing protective sleeve must take the weather into account, the humidity during the construction should be less than 70RH, and the total direct sunlight exposure time of more than 12 hours must be available within 48 hours after the construction (only for pipeline crossing).

6.2 The inner side of the light curing protective sleeve is cloth, and the outer side is felt. The cloth side faces the pipeline, and the felt side faces out. If reversed, the light - cured protective sleeve will not provide protection.

6.3 For specific construction methods, see the technical specifications of related structures.

6.4 Construction technology key and requirements of light curing protective sleeve:

6.4.1 Shielding uv rays is very important, which can greatly prolong the effective operation time;

6.4.2 The end of the main operator must pass through the top of the tube, otherwise the deputy will loose when strained;

6.4.3 The tension must start from the middle, so as to ensure that the lower part of the middle concave can be contracted and extruded;

6.4.4 The edges shall be fitted and the whole shall be wrinkle-free. The transparent tape shall be in the correct direction and tightly wound to ensure the quality;

6.4.5 Construction quality requirements: fitting, no wrinkles, no warping edge. For specific construction technology, please refer to the construction technical scheme manual provided by our company.