I. Product introduction

This product is epoxy coal asphalt glass cloth anticorrosive layer replacement products, this product is composed of two parts of the base band and shaping glue, the base band is soaked epoxy base material glue polypropylene non-woven cloth, replacing alkali, wax containing glass silk cloth, shaping glue is non-solvent epoxy coal asphalt coating, replacing the solvent type epoxy coal asphalt coating.

In order to meet the requirements of national standard GB 50268, China Petroleum Standard SY/T 4007 and Sinopec standard SH 3022 for a variety of anticorrosive coating thickness, we can provide three types of products, namely: Anticorrosion layer combination thickness 0.4㎜ GH 401 strengthen level, 0.6㎜ GH 402 special strengthen level and 0.8㎜ GH 403 thickening level (that is, sinopec standard special strong level). In order to adapt to the large temperature difference between north and south China, according to the construction environment temperature will be supporting the stereotype glue is divided into three types, namely: normal temperature glue (J type, 5℃ above use), low temperature glue (D type, -5℃ above use) and ultra-low temperature glue (E type, -5℃ below use).

The product passed the appraisal of Beijing Municipal Administration Committee in 2004, and is considered to be convenient for construction, reduce cost, improve anti-corrosion quality, and be conducive to improving environmental protection. It has reached the leading level of epoxy coal asphalt anti-corrosion materials in China, and can be popularized and applied in municipal engineering.

Two, product features

1, polypropylene non-woven cloth does not contain wax, alkali, eliminate the glass fiber cloth with wax, alkali caused by poor adhesion and high water absorption, acid, alkali, salt erosion defects, greatly improve the coal epoxy asphalt coating adhesion, mechanical strength and anti-corrosion performance in salt and alkali area.

2, shaping glue is solvent-free formula, dense coating, no pinhole, greatly improving the quality of anti-corrosion layer.

3, the use of two glue (or three glue) belt construction process, instead of the original standard requirements of three oil a cloth strengthening and four oil two butte strong and sinopec five oil three butte strong. Simplify the construction process, shorten the construction period, improve the efficiency, save the project cost.

4, this product can be in different environmental temperature construction of three kinds of shaping glue, can be in any place, any season, any temperature conditions under the construction, so that the epoxy coal asphalt anti-corrosion can be all-weather construction, to solve the original standard of a variety of harsh environment can not construction defects.

5. The base band and forming glue of this product are supplied together to improve the degree of preparation of epoxy coal asphalt coating in site construction. After construction, the coating has uniform thickness, stable quality, beautiful appearance and excellent anti-corrosion performance.

Three, scope of application

Suitable for underground and underwater steel oil, natural gas, tap water, heating pipe wall anticorrosion, also suitable for steel tank tank bottom and sewage tank, roof waterproof layer, toilet, bathroom, basement and other concrete structure waterproof and anti-leakage.

Iv. Technical indicators

The appearance of the product, the thickness of the anticorrosion layer, the main technical indicators of the spark leakage detection voltage are in line with the corresponding requirements of the national standard GB 50268, the petrochemical standard SH 3022, the petroleum standard SY/T 0447 and other standards.

Technical specifications of cold winding of epoxy coal pitch

| Serial number | Project | Unit | 技术指标 | ||

| GH 401 | GH 402 | GH 403 | |||

| 1 | Baseband width, | mm | 125±2.5 | 250±5 | 400±8 |

| 2 | Base band tensile strength, | N/cm | ≥20 | ||

| 3 | Setting glue drying tim e(25℃,action) | h | ≤16 | ||

| 4 | Bonding strength of set adhesive (drawing method) | MPa | ≥5.5 | ||

| 5 | Color and appearance of anticorrosion coating | 黑色有光、表面平整、粘结紧密 | |||

| 6 | Thickness of coating | mm | ≥0.4 | ≥0.6 | ≥0.8 |

| 7 | Anticorrosion coating leakage detection by electric spark | kV | 2.5 No funnelled | 3.0No funnelled | 5.0No funnelled |

| 8 | Adhesion of anticorrosion coating (Tearing method) | — | No funnelled | ||

| 9 | Impact resistant coating | J | 4.9 The impact point is not exposed iron | ||

Five, use method

1, with shaping glue. Component A: Component B = 1:1 (weight ratio).

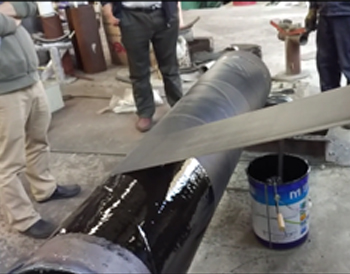

2. Construction sequence. Gluing - taped base band (base band is not positive or negative) - gluing - curing health.

Note: If you need detailed construction method, please ask our company for construction operation instruction.

Vi. Product packaging

The products are packed in cartons and pasted with certificate of quality. Each box is loaded with 10㎡ base band and 1 kg of molded rubber A and B, with A net content of 4kg for GH 401, 5kg for GH 402 and 6㎏ for GH 403.

Supporting diluent is packed in small iron drum with net content of 10kg per barrel.

When ordering, it is recommended to estimate the amount of cold winding tape according to 1.1 times of the actual anticorrosive area, and take the number of rounded boxes.

Seven, notes

1, must support the use of our company's supply of baseband, shaping glue (including A, B components) and cleaning thinner.

2. The quantity of shaping glue in each box is only the normal amount of anticorrosive layer standard structure construction. If the user needs to finalize the glue with putty or increase the number of times coated brush, should be added to purchase finalize the glue.

3, transportation should be light and light unloading, the carton is placed, to prevent rain, avoid sunlight exposure.

4, storage should keep the original packaging, stored in the fire protection measures qualified warehouse, up to 4 layers, since the production date storage period of one year, expired products such as technical performance in line with the enterprise standard can still be used.